There are three types of treatment systems for Marine Waste:

Electrolytic (on-line treatment)

Physical/Chemical treatment

Biological (or Aeration) treatment

The OMNIPURE IMO/USCG Certified treatment process from STDN is the ONLY electrolytic type sewage treatment unit available on the market that oxidize sewage in the electrochemical cell as well as generate NaOCL for the disinfection of the marine waste streams.

The Electrolytic Treatment advantages are:

Requires less installation space 10 times smaller than other systems

Unit operating weight is up to 10 times less than other treatment systems

No dangerous and costly storage of chemicals or chlorine is required

Complete unit is modular and skid mounted

Complete treatment of influent occurs in approx. 30 minutes, as compared to 30 hours with other systems

Can be used onboard oceangoing vessels and production platforms

More sanitary when performing simple maintenance

True on-line operation, with no adverse effect when unit is turned off

No microogranism colony to keep alive

No additional disinfection chemicals or additives are required

Not affected by sea motion

No bark to replace

Easily accompanies various vacuum collection systems

Large units can be automated to lessen intervals between manual routine maintenance

USCG Required NRTL Type Certification for entire product line for units used in classified, hazardous areas as defined by the National Electric Code (NEC)

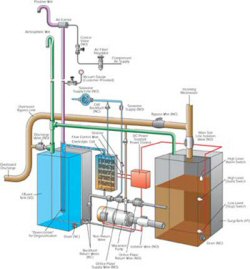

The function and operation of every OMNIPURE unit is the same regardless of size. The process is simple and proven effective.

On-demand Operation

Incoming sewage and wastewater is first collected in the V-1 Surge Tank. The treatment cycle begins when the wastewater triggers the High Level Start Switch.

The Macerator Pump effectively grinds the raw sewage down to a max particle size of 1/16 inch. As it removes the wastes from the V-1 Surge Tank, a measured amount of the macerated sewage is returned to the macerated stream. A percentage of the macerated sewage stream is returned to the V-1 Surge Tank for reprocessing. The slurry of the seawater is electrolyzed in the cell. The result is a total bacteria kill and a rapid 90-95 percent oxidation of the sewage stream.

The treatment cycle ends when the level in the V-1 Surge Tank drops to the Low Level Switch. The system is now in stand-by mode. A High Level Alarm Switch is provided to monitor high sewage levels in the V-1 Surge Tank.

Automatic Operation

Onsite Oxidant Generation

The treated wastewater enters the quiet zone of the V-2 Effluent Tank, where the required 30-minute residence time allows for the completion of the process. The treated effluent is discharged to sea, in accordance with USCG/IMO standards.

Local control panel ensures safe and efficient operation of the treatment process

Local switches and status indicators allow for simple operator interface

The electrolytic process naturally generates a minimal amount of hydrogen and carbon dioxide. These byproducts are safely and efficiently diluted with air and discharged into the atmosphere via an air ejector or a blower.

Available Certifications:

International Maritime Organization (IMO) Resolution MEPC.2 33 CFR 59

United States Coast Guard (USCG) Type Test Certified

Certified for use in Hazardous Areas per NEC 501-1 of NFPA 70 (CL.1, C/D, Div.2)

China Classification Society No. NYT02610001

Russian Maritime Register of Shipping No. 97.143.009

Certified by Nationally Recognized Testing Laboratory (NRTL)

L508A

UL73

NFPA 70, UL1604 and NFPA 496

UL698A

Applicable sections of Article 500 of the National Electric Code (NEC)