Air Eliminators and Combination Air Eliminator Strainers offered by IndMac are designed to provide separation, elimination and prevention of air in piping systems for a variety of installations and conditions.

Positive displacement and turbine meters, being volumetric measuring devices, cannot differentiate between liquid, air and vapor. Although the air content, in most instances, is small when compared with the product, it will contribute to measurable error. Large amounts of free air or vapor entrapped in a piping system, not only compromises meter accuracy

but can lead to overspeeding of the measuring unit, creating excessive wear or possible unit failure. To insure accurate liquid measurement, it is necessary to remove all vapor and free all entrained air from the system prior to entry into the measuring unit.

Design Features

High capacity air elimination provides maximum meter protection and superior measurement accuracy

Large screen area means less frequent cleaning

Vertical tank facilitates installation

Wide variety of materials, screen sizes and pressure ratings

Easy maintenance

Carbon Steel or Aluminum body construction

Ductile Iron, Steel or Aluminum eliminator head

Principle of Operation

Air Eliminators decrease the velocity of the flowing stream and bring the liquid to a state of relative calm so that air bubbles or vapor will rise. As air and vapor collect in the top of the vessel, liquid volume is displaced.

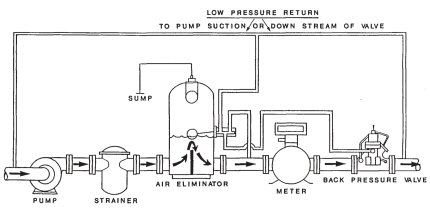

Once displaced to a predetermined point, a float operated valve opens and the accumulated air and vapor is discharged from the tank. Liquid level then rises, causing the float-operated valve to close. Discharge rate is regulated by back pressure on the outlet side of the eliminator. If sufficient pressure differential is not available to maintain a proper rate,

a back pressure valve should be installed.

Installation of the air eliminator must be on the upstream inlet side of the meter on the discharge side of the pump. Discharge may be vented to the

meter outlet, back to storage, or into a sump, condensation drum or tank.

CAUTION: Local regulations should be checked prior to venting to atmosphere or an open vessel.

Applications

In most applications, free air is eliminated without difficulty. Air which has become entrained in the product and carried along with the stream, however, must be separated from the liquid product and collected as free air before it can be discharged effectively. Entrained air in gasoline and low

viscosity products separates and rises to the surface quite rapidly when the liquid velocity is decreased sufficiently. As viscosity increases, the rate of separation and rise of entrained air decreases and more retention time is required to effect surface operation.

Because tank size is a consideration in the storage and dispersal of collected air and vapor, it is not always economical to remove entrained air from the system. When considering installations handling such products as heavy oils, it is usually far more economical to prevent the entrance of entrained air rather than eliminate it.

Products such as fuel oil, diesel oil and kerosene have a tendency to foam, causing air to be discharged in the form of vapor. Petroleum products in this form are hazardous when discharged to the atmosphere and, for this reason, require large air eliminators to accommodate increases in surface tension.

Selection of the Air Elimination Device:

Air Eliminators for a given job should be selected on the basis of flow rate, viscosity and the magnitude of the air problem incurred. Normally, the problems incurred that require the elimination of free air can be classified in one of three conditions:

1. Venting Free Air from a Piping System - Starting a New Installation or Filling a System After Drainage

In most cases, a simple air elimination device combined with a strainer will perform satisfactorily and is the most economical method. This combination offers protection of the meter against intrusion of foreign material and eliminates free air that could cause meter inaccuracy.

CAUTION: During start-up or after maintenance, slowly purge the line until it is filled with liquid and all air and vapor have been removed.

2. Moderate Amounts of Air Requiring a Separate Air Eliminating Vessel and Venting Device

In applications involving moderate amounts of free or entrained air or when highly viscous products are being measured, an elimination tank is

recommended for proper retention time. It is required a reduction in product velocity as well as more retention time before release of air or vapor, thus the need for a larger receiving/holding tank. Applications

common to this condition include those which have allowed the product tank to completely empty, failed to properly close a valve, very low storage tank levels or have been loaded and unloaded through a

common line. This condition is limited to those applications in which no high, continuous volumes of entrained gas or air may result from either system failure or human error.

3. Critical Conditions Involving Large Amounts of Air or Gas Entrainment

Typical applications may involve:

Unloading transport trucks, tank cars or pumping from barges or tankers

Pumping from underground storage

Piping systems used for several different operations and products (air is introduced when changing products)

Lines with occasional drainage between products

Above-ground and heat-absorbing lines exposed to the sun can result in the release of solution gases and boiling of light ends where high vapor

pressure products are utilized

Pumping in and out of the same line

High turbulence created by high liquid velocity, valves, fittings, etc.

Viscous products greater than Number 2 Fuel Oil

Lines blown down with compressed air or those allowed to run dry

Conversions

Existing strainers may be converted for air elimination by adding an air eliminator head assembly. Please contact IndMac and its application engineers for more information.